![]()

Stockhausen Slit Drum

On the heels of the Heaven's Door commission, Stuart has commissioned these instruments to perform Stockhausen's "Zyklus" and "Kontakte". I am building these out of the same quarter sawn sapele that was used for the Heaven's Door plates. The instruments manufactured by Kolberg Percussion GmbH, Uhingen, Germany are tooled on their outer surface to resemble natural log graining, no doubt contributory to their inflated cost. We are not reproducing this effect. Below are some study photos taken by Stuart of the Kolberg instruments

Photos by S Gerber

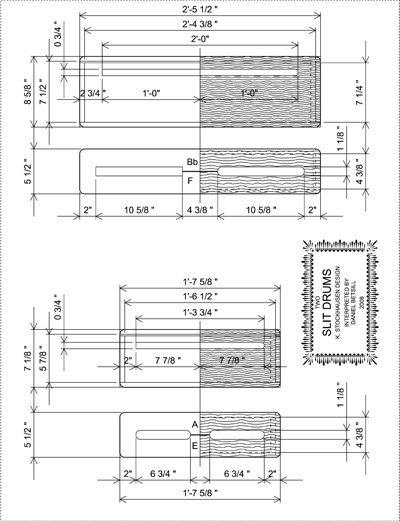

My drawing based on Stuart's field dimensions. (above) Process photos following. My addition to the original design is a reveal that occurs around the top of the carcus that will allow us to easily interchange the top plate.

The larger of the two slit drum carcuses is dry-fitted. Showing the tracking grain from the end around to the side. Before assembly the sides will have the sound hole (slot, more like) routed.

++++++

Routing the sound hole slot and clamping up the first carcus

++++++

The larger of the two drums has the corners radiused and the rebate along the top edge has been routed.

Close-up of the rebate

Inside view of a typical end with the interior liner block angled back so as not to contact the top. Only the thin rebated edge contacts the underside of the top. The rebate creates a continuous edge to separate the top from the carcass. This will be a hide-glue joint to make disassembly of the top easier.

++++++

The carcasses are complete.

The template for routing the slot in the top.

One of the top slots for the small drum is cut

The small drum top is complete and is glued on to the carcass. I am using hide glue so the top can be easily removed should it need to be remade for repitching.

This is the top for the long drum, showing the rebate at the thick edge. The drums produce two different tones based in part on the thickness of the top. These are two boards of contracting thickness laid up. But because the top edge of the carcass is consistent, a rebate must be made along the thick side to flush it out with the thinner side. Through reverse engineering the Kolberg drums we discovered that the "soundhole slots" in the sides are infact not soundholes but primarily tuning slots. The longer the slot, the greater the ability for the top of that side to vibrate at a longer waveform and therefore a lower pitch. So we shall henceforth refer to these slots as "tuning slots". The enlarged openings in the top is more accurately the "soundhole".

The long drum is finished. I am using tung oil to finish them. I have recently had the epiphany of avoiding finishes with strong VOC's like nitrocellulose lacquer for natural finishes like tung oil, which has excellent water resistance and doesn't kill you.

++++++

OK, now that we know how the "tuning slots" work, I have made another set of drums which are fully assembled before the slots are cut. Here is the jig I made to clamp to the finished carcasses to tap the 3/4" wide slot. The router is moved in increments of 5mm symmetrically about the centerline until the desired pitch is obtained.

The drums are complete.

++++++

Some months later - after at least two performances with the drums placed on music stands - I have completed a specialized stand for the instruments. Kolberg Percussion makes a stand for their version of these instruments which is metal and holds the drums at their ends. Following what I learned from the Heaven's Door project about vibrating chunks of wood, I felt that likewise the slit drums perform more like a resonating bar rather than a soundboard and therefore it made more sense to suspend them at their natural fundamental nodes, some distance in from the edges. So I have created cradles for the instruments which touch in three places at small rubber bumpers. The secondary advantage of this stand is it folds; the hinges taking the place of a mortise-and-tenon joint between the posts and rails. The arms are adjustable both in and out and up and down. I think having a wood stand for a wood instrument is also nice.

++++++

Some years later I was commissioned for a second set of drums. . .

Monday, October 7, 2013

.jpg)

.jpg)

.jpg)

Progress on the Stockhausen slit drums. The top plate is routed, shaped, then the slot sawn to create the two 'tongues'.

++++++

Tuesday, September 24, 2013

The beginnings of a set of Stockhausen slit drums: planks of 4/4 sapele. The top board is planed.

Bring it HOME.